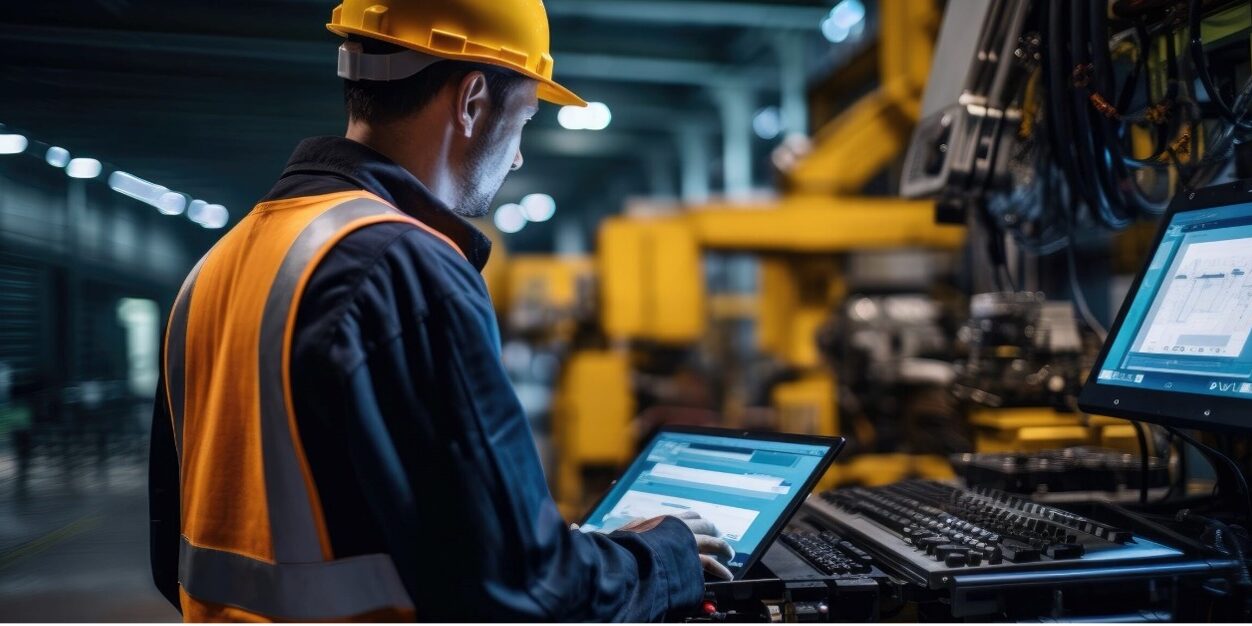

In today’s world, the industry is shaped by constantly evolving technological innovations, and one of the cornerstones of this evolution is industrial automation systems. Automation revolutionizes the industrial sector by increasing efficiency in production processes, reducing error rates, and directing workforce towards more strategic tasks.

What Is Industrial Automation?

Industrial automation aims to automate various tasks in the production process without human intervention. This system manages processes through computers, robots, sensors, and control systems. Industrial automation offers many advantages such as cost reduction, increased production speed, and improved quality.

Key Elements Of Industrial Automation Systems

- PLC (Programmable Logic Controller): PLCs are considered the brains of industrial automation. These specialized computers analyze inputs (sensor data) in a specific process and control outputs (such as motors, valves).

- Sensors and Actuators: Sensors measure various physical variables and transmit this data to the PLC. Actuators initiate physical movement based on commands from the PLC.

- HMI (Human Machine Interface): HMI screens allow operators to monitor and control industrial processes. These user interfaces graphically display process data, facilitating interaction with the system.

- Industrial Robots: Robots are used to automate various tasks in production lines, supporting human labor by performing tasks like welding, assembly, and packaging.

- SCADA (Supervisory Control and Data Acquisition): SCADA systems are used to monitor and control large-scale production processes. These systems collect and analyze data from sensors, providing real-time information to operators.

Advantages Of Industrial Automation

- Increased Efficiency: Automation makes processes faster and more efficient, reducing time losses in production.

- Error Reduction: Automation minimizes human errors, enhancing product quality.

- Cost Reduction: Automated processes decrease labor costs, leading to long-term savings.

- Flexibility: Industrial automation makes production lines more flexible, enabling the quick production of different products.

- Safety: By reducing the need for human presence in hazardous environments, automation enhances workplace safety.

The Future Of Industrial Automation

In the future, industrial automation will become more integrated with technologies such as artificial intelligence, machine learning, and big data analysis. This integration will lead to smarter and more predictable production processes, further increasing the advantages provided by industrial automation.

Industrial Automation İn Our Company

With years of experience and expertise in industrial automation systems, our company offers customized solutions to customers in various sectors. Focusing on optimizing production processes, we provide tailored automation solutions that meet customer needs for each project. In our applications, we work in collaboration with solution partners such as SIEMENS, ABB, SCHNEIDER ELECTRIC, OMRON, SICK, DANFOSS, BANNER, FESTO, EAE, BEIJER ELECTRONICS, and KHRONE brands.

Investing in the future, we continue to provide the best service to our customers, recognizing that industrial automation is the key to sustainable success and a competitive advantage in the business world.

For Questions and More Information:

- Email: [email protected]

- Phone: +90 (312) 429 00 56

- Fax: +90 (312)429 01 08

- WhatsApp: +90 (535) 104 18 66