In industrial automation systems, data transmission and interaction between different devices play a crucial role. Modbus is an open communication protocol widely used for such applications. In this article, we will explore what Modbus is, how it works, and its utilization in industrial systems.

What is Modbus?

Modbus is an open standard used as a serial communication protocol among industrial devices. The protocol enables devices to share data and transmit control commands. Initially developed by Gould-Modicon in 1979, Modbus is now extensively employed in many industrial automation systems.

Types of Modbus

The Modbus protocol comes in various variations for different communication environments and devices. The most commonly used types of Modbus are:

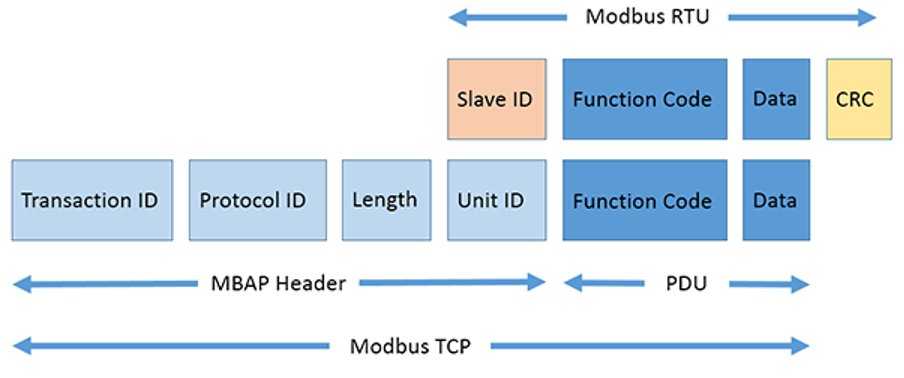

- Modbus RTU (Remote Terminal Unit): RTU is a format used for serial communication, typically employing serial connections like RS-485 or RS-232. It ensures reliable transmission of data over long distances, even up to thousands of meters.

- Modbus ASCII (American Standard Code for Information Interchange): ASCII is a text-based format providing human-readable data. Similar to RTU, it can work over RS-485 or RS-232.

- Modbus TCP/IP: Built upon the TCP/IP protocol suite, it operates over Ethernet networks, offering communication over LAN or WAN in industrial automation systems.

How Does Modbus Work?

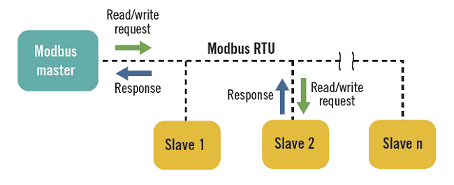

Modbus communication usually involves a master unit and one or more slave units. Communication occurs as the master unit sends a command to perform a specific task to the slave unit, which responds accordingly. Each device is identified by a unique address, and data exchange takes place through Modbus frames.

The Modbus process involves the following steps:

- Request: The master unit sends a request to a specific slave unit to perform a task.

- Function: The slave unit executes the received request.

- Response: The slave unit sends a response concerning the completed task.

These steps enable continuous data exchange in industrial automation systems, ensuring effective system operation.

The Role of Modbus in Industrial Applications

Modbus provides several advantages in industrial automation systems:

- Universal Standard: Modbus is a universally supported standard, allowing devices from different manufacturers to communicate with each other.

- Simplicity and Efficiency: Due to its simplicity and lightweight design, Modbus is preferred in industrial environments. This simplicity ensures effective communication even in devices with low system resources.

- Flexibility: Modbus can be adapted to different communication environments and device types. This flexibility makes it ideal for a wide range of industrial applications.

Maytek Enerji and Modbus

At Maytek Enerji, we ensure the efficient and reliable use of the Modbus communication protocol in industrial facilities. We provide solutions that facilitate seamless data exchange and interaction between different devices for our customers. Contact Maytek Enerji to maximize the advantages offered by Modbus and optimize your energy systems!

Modbus is a reliable and widely used communication protocol for inter-device interaction in industrial automation systems. Despite its simple fundamental principles, it proves to be flexible and efficient for a broad range of applications. Modbus appears to maintain its significance for many years to come for applications requiring data sharing and control in industrial facilities.

If you need more information or want to learn about a specific topic related to Modbus, please feel free to contact us!

For Questions and More Information:

- Email: [email protected]

- Phone: +90 (312) 429 00 56

- Fax: +90 (312)429 01 08

- WhatsApp: +90 (535) 104 18 66